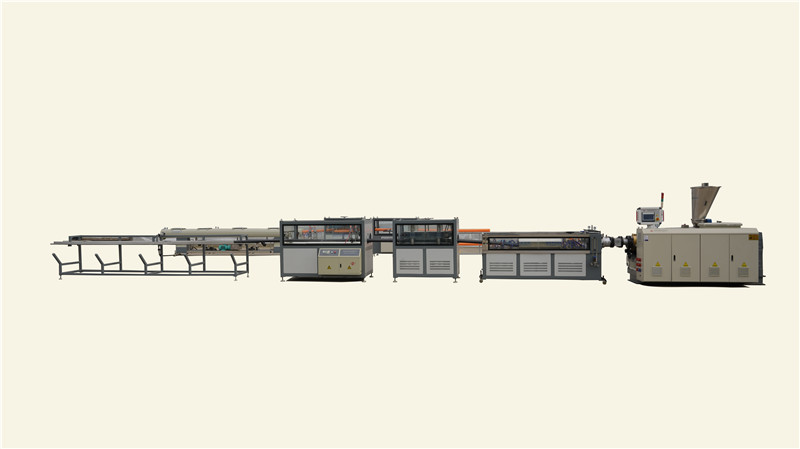

HDPE cavum Wall Curvis Pipe Productio Line

extrusio lineae maxime ad parietis curvae fistulae cavam producendam.HDPE tibia curva concavitas parvas massas habet et asperitatem coëfficientem habet, late ad systemata purgamentorum, cloacarum tempestatum, curatio facilitatum et sanitationum pipelini veteris, bene et variae piscinae purgamentorum conficiuntur.Tibiae cum diametris ab 200mm-4000mm et in generibus rigoris SN 2,4,6,8,10,12,14,16.Tuba extrusio recta primum fistulas quadratas ab HDPE producit, deinde machinae machinae coaeternae et spiralis machinae ope coaeternae in parietes vulnerant et deinde simul corpus organum formantes iuncta sunt.Tibiarum extrusio et ratio flexuosa separatim moderata, separatim adhiberi possunt.Recta industria salutaris, facilis ad transportandum et institutionem, collocatio inferior est, facilis ad conservandum.

extrusio linea cum technologia proficit designata et nonnullae technologiae patentes nostrae societatis adhibitae sunt.Maximum celeritatem et excellentem extrusionem qualitatis, adhibendo duos terminos unius cochleae extruder cum magna effectione efficientiae.Unicum consilium compositorum capitis morientis per magnum diametrum tibiam curvis processus cum efficientia alta producendi.Princeps qualitas tibiae curvae productae adhibito processu unico flexo.Machina secans potest eligere unum machinam secantem vel stamina incisionem et machinam integratam molendini, cum bona signatione et factore salute alta.Omnes partes lineae productionis currunt in operatione perfecta synchronisationi facili et perfectae operationis, adhibito PLC progressivo systematis temperantiae tactu LCD.

SCHG-630-1600(600,700,800,900,1000,1200,1400,1500,1600MM)

DIAMETROS CAVUS MURIES GRAVALIS Fistulam magnam LINEA

ENVIROMENT A. EXERCITATIO:

| landnon-periculum zone85% non-condensation0~40℃ | |||

B. CONDICIONE USUS:

machina electrica propter incessus: usus est ad arbitrium et imperium ratio:

| 3P 380V(-10%,+5%) 50HZSingle phase 220+ 10% 50HZ15℃-26℃ pressure≥0.3MPa≥0.6-0.8Mpa | |||

C. MAIN ARTI PARAMETRUM PRODUCTIONIS LINEA

| Involve-and-spliceDiameter:800mm~1600mm, longitudo:6000mm,8000mm.PE vel reciyle granules650kg/hFrom ius ad sinistrum ~ 350kw~220KWblue,album vel elit praebent colordisc30000mm×18000mm×3800mm~ 22000kg | |||

D. APPARATUS

| 1set1set1set1set1sets1set1set1set1set1set | |||

E. ARTI PARAMETER OFFICINARUM

| Ⅰ.Hollow quadratum extruder exemplar:SJ100X301.1 type1.2 Centrum height1.3 Max output2.screw1.diameter2.L/D3.material4.Superficies treatment5.profundum nitration 6.celeritas gyrari 3. apparatus dolium 3.1.materia 3.2.Superficiem treatment 3.3.profundum nitration 3.4.calefactio zonam 3.5.calefactio genus 3.6.calefactio virtutis 3.7.refrigerandum genus 3.8.refrigerandum potentia 4. positivum calces arca 4.1 materia de arca 4.2 genus calces 4.3 materia calces 4.4 axe 4.5 materia axis 4.6 systema lubricationis 5. principalis electrica machina 5.1 genus machinae electrica 5.2 potestas machina electrica 5.3 celeritas gyra 5.4 leo 5.5 potentia 6. loading apparatu 6.1 genus 6.2 potentia 6.3 max deferat facultatem | Una cochlea extruder1000mm600kg/h100mm 30 38CrMoAlA nitrogen 0.50-0.70mm 0-140r/min 38CrMoAlA nitrogen 0.50-0.70mm 6 Calefaciens torquem Ceramic 56kw CERAULA refrigerandum 0.25kwX6 HT200 revellere coneris; 20CrMnTi, carburation, exstinguendi importari 40Cr Pressura lubricationis AC motor 90kw 1500 r/min 1set (ABB) 3p* 380V*50HZ Vacuum loading automatice 2.2kw 1000kg/h | ||

II.conflator generis extruder rubberSJ75X30 1.main motor1.1 type1.2 center height1.3 max output2.screw2.1 diameter2.2 L/D2.3 material2.4 superficies treatment2.5 profunditas nitration2.6 rotata speed3.apparatus dolium.1 materia | (Agitur prohibendo marinis corrosio) Una cochlea extruder1000mm220kg/h75mm3038CrMoAlAnitrogen0.50-0.70mm0-140r/min Una cochlea extruder1000mm220kg/h75mm3038CrMoAlAnitrogen0.50-0.70mm0-140r/min38CrMoAlAnitrogen0.50-0.70mm5Ceramic calefaciendi monilia 25kw CERAULA refrigerandum 0.25kwX5 HT200 revellere coneris; 20CrMnTi, carburation,queching importari 40Cr pressura AC MOTOR 55kw 1500 r/min 1set (ABB) 3p* 380V*50HZ Vacuum loading automatice 1.5kw 800kg/h* | ||

Ⅲ.cavae quadratum stirpe extrudendo mori caput

| incomingStain chalybe calefactio collar15KW | ||

IV.SFZC concavum , truncum quadratum vacuum , formans piscinam aquae

|  1set6000mmStain steel164pcs14kw14kw+ 500mm0.75KW+ 50mm1200mm6250mm780mm~1600kG 1set6000mmStain steel164pcs14kw14kw+ 500mm0.75KW+ 50mm1200mm6250mm780mm~1600kG | ||

V.SFPC cavata stipite quadrato imbre piscinae aquae

| 2setSpray cooling6000mmStain steel13kw124pcs1100mm6250mm780mm~1200kg | ||

VI.SRHJT-50 caput mori Flexilis liquefactum welding

| 1set20mmCenter advenientis stock3Cr176KW | ||

VII.CRFJ-1600 tibia curva machinae formans 1.max diam2.exemplar positivum calces box3.ventus calidus power4.frequentia controller5.total6.tractus7.forma dimensio 1.max diam2.exemplar positivum calces box3.ventus calidus power4.frequentia controller5.total6.tractus7.forma dimensio | 2000mmX153kwABB22KW200KN3500mmx3000mmx3600mm | ||

Ⅷ.SDQGJ-1600 machina secans fistula

|  350mm2000mm3KW600mm 350mm2000mm3KW600mm | ||

Ⅸ.SGXL-1600 unloading bracket

| Pneumaticum unloading6000mm | ||

X. Temperature systemate imperium

| SIEMENSRKCABB | ||

Ⅺ.libera parce partes cum apparatus (II annis consummatio)

| exemplar | Parce partes | moles | dicta |

| SJ100X30SJ75X30 | Dolium machina thermoelectric par | VI PCs | |

| Virtus off praesidium | VI PCs | ||

| AC contactor | VI PCs | ||

| Medius contactor | 6pcs | ||

| button | 6pcs | ||

| Optio switch | 6pcs | ||

| Labe ferro calefaciendo torquem | 3set | ||

| controller | 3pcs | RKC、FUJI | |

| O genus anulum | 3set | ||

| Apparatus axis oiltight | VI PCs | ||

| Temperature moderatoris | VI PCs | ||

| Electric carbonis penicillo | 3sets | ||

| Crucem cochlea exactoris | 2pcs | ||

| Recta stupra exactoris | 2pcs | ||

| Generalis utilitatem clavis | 2pcs | ||

| Interiorem hexagonum spanner | 2sets | Electus a fingunt | |

| vacuum (imbre) inspectionem aquae piscinae 100 | nilometer | 12pcs | |

| slirubber | 6㎡ | ||

| Parce signantes partes | 50~60m | ||

| Unius nuzzle | 100pcs | ||

| Virtus off praesidium | 8pcs | ||

| AC contactor | 8pcs | ||

| Medius contactor | 8pcs | ||

| Electromagneticum valorem | 6pcs | ||

| Formatio machina 2000 | Rollerus axem | 20 pcs | |

| axem | XXX PCs | ||

| Secans fabrica 105 | Videns frenum | 6pcs | |

| Electromagneticum valorem | 6pcs | ||

| Electromagnetic switch | III PCs | ||

| Aeris tube | 50m | ||

| Tubus mollis | 15m | ||

| faucium os | 10pcs | ||

| Quadratus pipe mori caput | Thermoelectric par | 3pcs | |

| Labe ferro calefaciendo torquem | 2set | ||

| Princeps viribus cochlea | 30pcs |